Gamecock, the last surviving oyster yawl built in Whitstable, has been saved from a watery grave by local charity Whitstable Maritime and is now undergoing restoration in Whitstable Harbour. Whitstable Maritime aims to use Gamecock to help people experiencing forms of disadvantage or barriers to accessing the many benefits local maritime heritage and the marine environment provide through a range of innovative educational and vocational skills training activities.

Gamecock’s Story

Built in 1906 by Collar Bothers, one of the ship yards that worked off the beaches at Whitstable, Gamecock is a 43 foot Oyster Yawl which plied the waters as part of a large oyster dredging and fishing fleet operating in The Swale and wider Thames Estuary.

Gamecock’s Story:

Once oyster dredging under sail became no longer viable, Gamecock passed into the ownership of Bill Coleman, a former oyster-man, and he kept her afloat until her maintenance costs became too much without the revenues she once provided from her commercial life at sea. In 2014, she lay decaying on Faversham’s saltmarshes and Whitstable Maritime took on the task of saving her from permanent loss.

Gamecock’s Restoration:

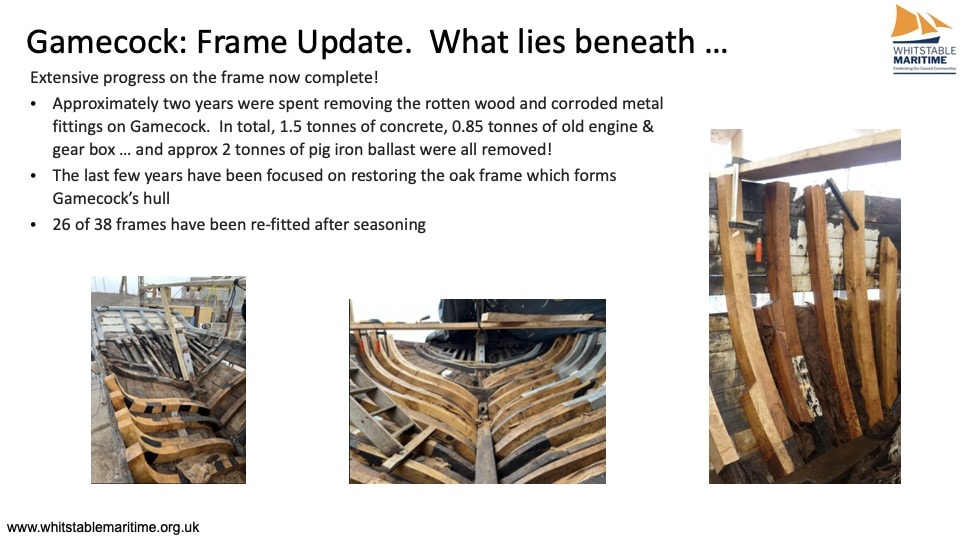

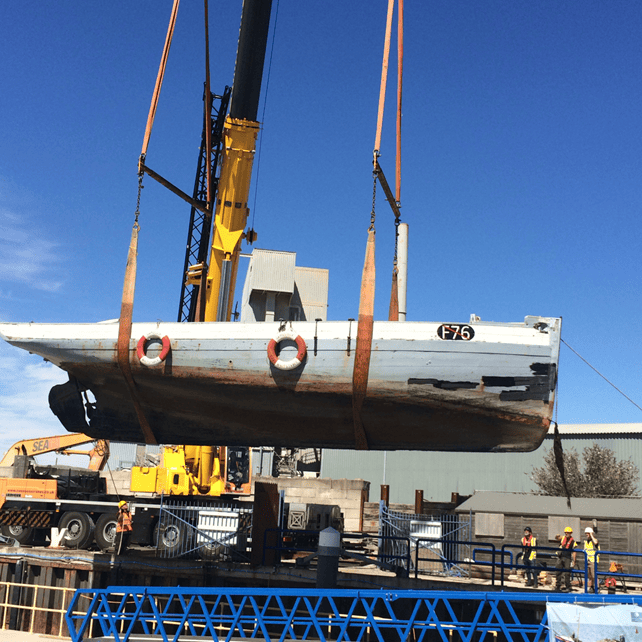

In July 2020, Gamecock was towed into Whitstable Harbour and hoisted onto the East Quay where space was kindly provided by Canterbury City Council’s Harbour Board. Morgan Lewis, a local shipwright, then set about the task of restoring her with a team of volunteers.

Her space in the harbour now comprises a mini ship yard in a nod to the thriving boat building industry that shaped the town and its connections to the sea and the oyster industry we find thriving here to this day.

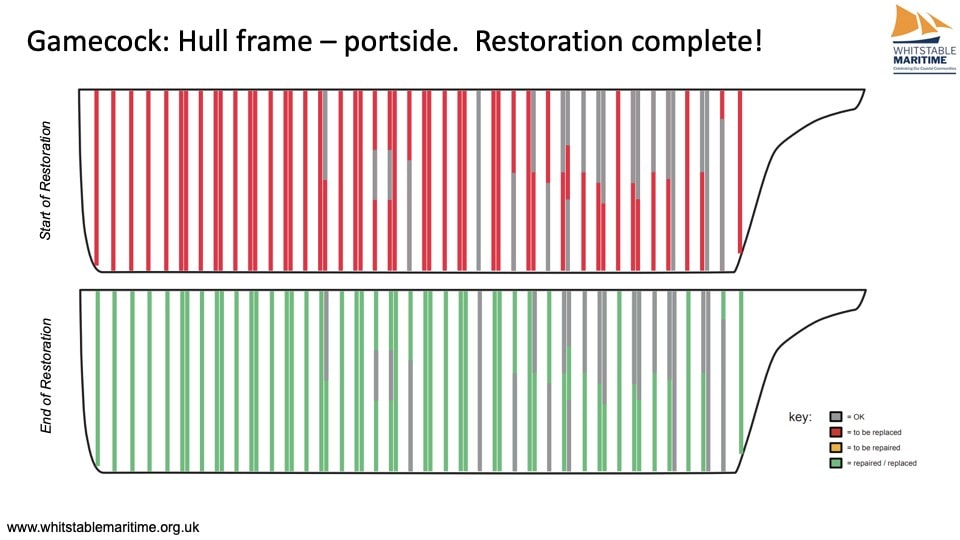

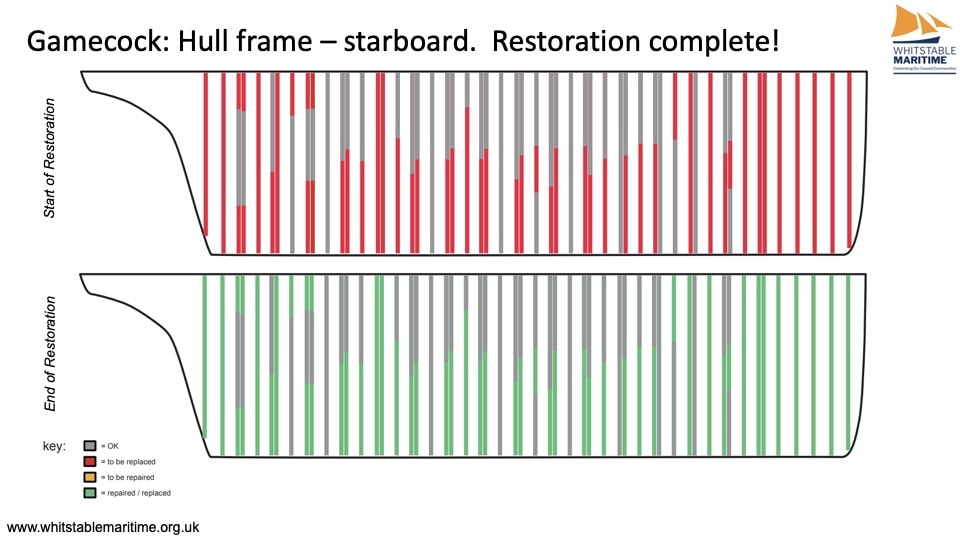

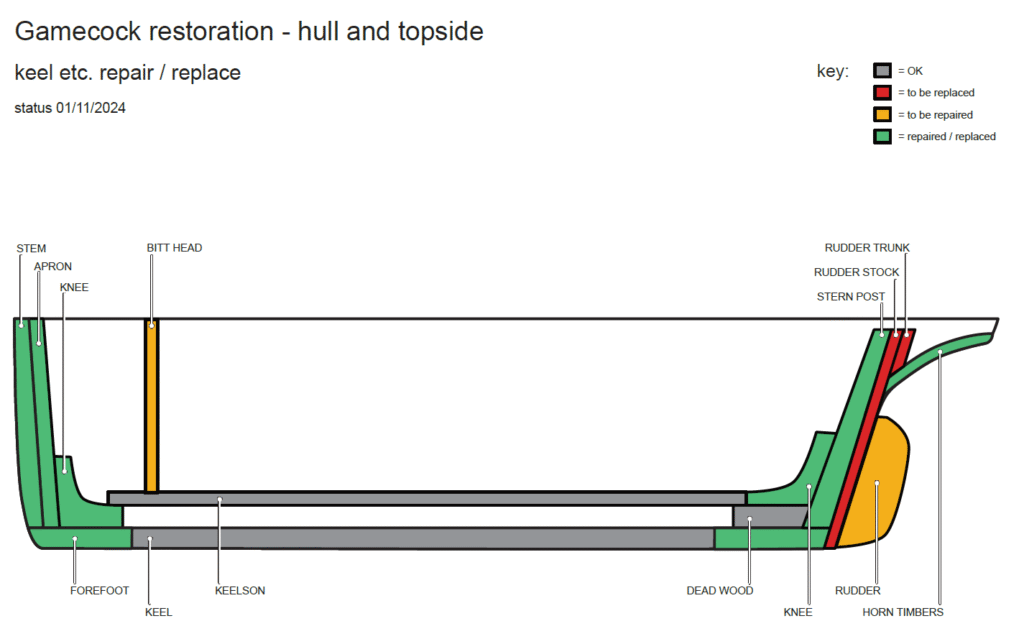

Progress has been as good as can be expected from a project that relies heavily on grant funding. All the main structural work on her hull and sides is complete which stabilises her condition and means all the ‘dead wood’ has been replaced.

Looking ahead, the challenge is to find funding to complete her restoration (decking, rigging, engine, internal refit) before she begins the exciting journey of her new life as an operational vessel sailing on the Thames once more.

Gamecock’s Future:

Providing learning, skills, experience and awareness of opportunity into wider employment with an emphasis on the UK’s maritime sector is a key role for Gamecock within our community.

Maritime UK has identified that the maritime sector does not have the strong awareness amongst schools and young people that it should and part of Whitstable Maritime’s vision for Gamecock is to provide a local level response to this problem.

The charity believes she can be an inspiration and opportunity for people to realise their potential, overcome the challenges they face and gain education and skills in a context not offered by mainstream education.

Education & Skills Provision:

The charity runs a work placement scheme with a maritime emphasis for Y12 students. Working on various aspects of the charity’s operation and in collaboration with other local maritime businesses and organisations, we want this to help inspire young people in our community to consider themselves as future leaders of the UKs maritime sector.

We also have a pathway to offering Gamecock as a work placement for apprentices through our relationships with nearby heritage boat shipyards seeking the unique opportunity of learning on Gamecock through her restoration and future, ongoing maintenance.

We also want to inspire younger learners so the charity aims to create a maritime heritage and oyster themed educational offer for KS2 learners using the forthcoming Education Centre in Whitstable Harbour. Coupled with time aboard Gamecock the aim is to build their sense of ownership over their town’s history and the opportunities it offers them growing up here now and in the future.

Beyond this, there is the opportunity for sail training and other informal educational activities both afloat and shore based which can be tailored to people according to their specific needs, e.g. around mobility or other specific learning requirements.

The education and skills sphere is a very exciting area for the charity as we look to shape a future for Gamecock that gives her and the wider maritime and oyster heritage she represents a renewed sense of purpose in the modern world, serving those most in need of help within our communities.

The charity is seeking donations, funding raising support and volunteers, especially in terms of the educational support required in this area of the charity’s work.

Article by Alex Hare included in MSA Newsletter, Nov 2025, Edition 4.

alex@alexharephotography.com

Maritime Skills Alliance – Home