The story so far ……

I am with Malcolm, Manager of Speyside Cooperage at Craigellachie Arberlour. We are in the warehouse looking out across several hundred casks ready for dispatch. At the far end about a dozen coopers are busy hammering metal rings over staves as they rebuild used asks for the drinks industry. The Company still builds or repairs over 150,000 oak barrels a year.

I am here following a chat with Jon, owner of The Foundry Brewery in Canterbury. Jon is brewing a premium rum to be called ‘Gamecock’ after Whitstable’s iconic 1906 Oyster Yawl. The rum is maturing in a large cask and that prompted us to start comparing the craft skills of the cooper with those of the shipwright. Clearly, both work in wood, the Cooper seeking to keep the liquid in, and the Shipwright to keep it out. Consequently they share some tools that have similar functions but the design of many has evolved to assist with particular tasks and these are unique to their respective trades.

Shepherd Neame never made their own casks but John, their Historian, found a large tin containing a set of cooper’s tools in a cellar of the Faversham Brewery. At the Speyside coopery, Malcolm was able to identify the Shepherd Neame tools. However, beware, there are variations in the terms used, both regionally and between the different specialisms in coopering: wet, dry and white.

Barrels and tubs were universal items in use for centuries, not only because they were convenient vessels for storage but also because they were easy to manoeuvre. If you are interested in learning more,‘The Cooper and his Trade’ (Linden Publishing 1989) by Kenneth Kilby is a good personal review based on his family’s engagement in the trade. ‘Coopers and Coopering’ (2004), also by Kilby, is a more concise and well illustrated account in the Shire series.

Gordon Vincent

- Draw Knife, Round Shave or Erasing Iron

Used for smoothing the inside of the cask by levelling the joints where the staves are ‘joined’.

If inside is left rough there is a risk of beer souring as bacteria collects. Wine and spirit casks were deliberately blistered and left rough for the liquid to take up the taste.

Smugglers used it for erasing brand marks on the head of the cask.

2. Crum Knife or Jigger

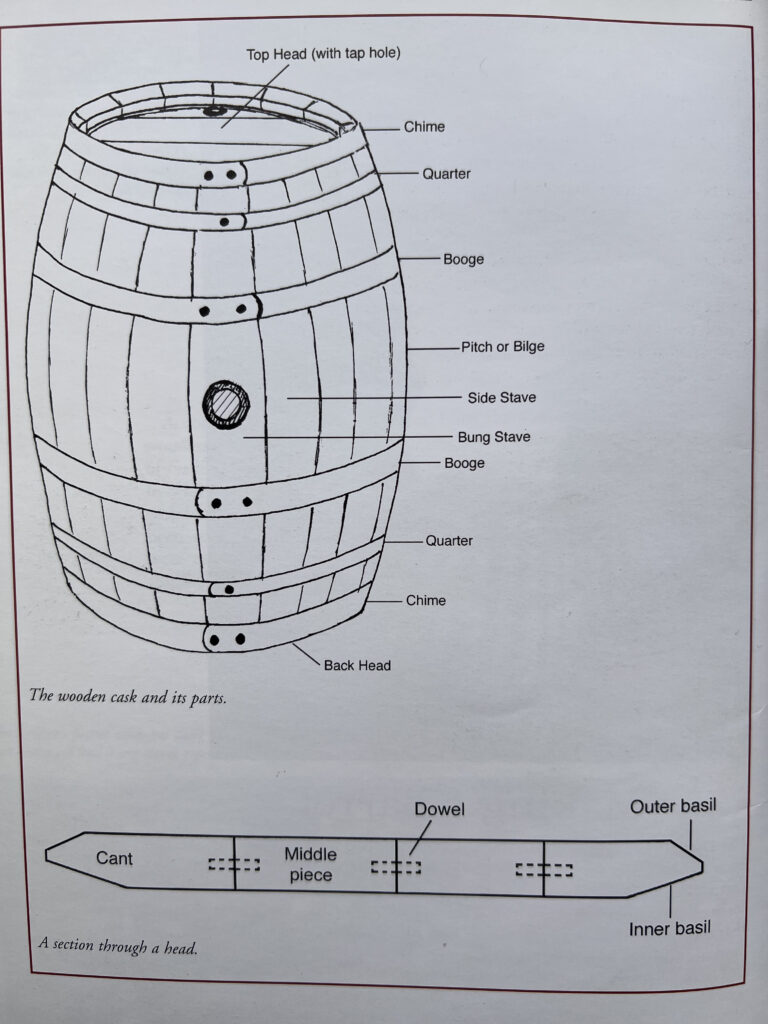

Used to smooth the inside of the chime in preparation for cutting the groove in to which the Top and Back Heads fit.

The blade is held in the left hand and swung with the right.

3. Flag Hook or Flag Iron

Used to force apart the staves so that the ‘flag’ can be inserted where the staves join. The flag is a rush grown for the trade which expands when it gets wet. Flag is also used to seal the dowelling joints that hold together the 3 or 4 sections of wood forming the Top and Back Heads. Shipwrights use ‘caulking cotton’ for a similar purpose.

4. Topping Plane

Used for levelling the tops of the staves at both ends of the barrel. A level top enables a more accurate circle for cutting the Head.

5. Skillop or Tapered Augur

Used for boring the first hole in the bung stave.

The bung stave is chosen for its strength and is about 2 inches thick where the bung is to be inserted.

6. Skillop or Bung Borer

Used for enlarging and tapering the bung hole. It could be turned clockwise and anticlockwise.

Repairing the bung stave was a lucrative sideline for the Cooper as it took a lot of strain and was usually the first to be damaged